Oceantech Shipping & Trading., Ltd can through its partners, assist your company in the installation and sales of marine GRE (Glass fiber – Reinforced Epoxy) / GRP (Glass fiber – Reinforced Plastic) and FRP Grading ship deck products. Our partners and principals have extended experience regarding these products and applications.

Product Solutions

We have been been working closely with an extensive list of domestic and overseas shipyards researching and developing the following products:

- GRE / GRP (Glass – Fiber Reinforced Epoxy & Piping) – Piping System

- FRP (Fiber Reinforced Plastic) – Marine Gratings

- GRP (Glass – Fiber Reinforced Plastic) – Cable Supportings

- Iron & Steel Outfittings

- Customized Products – Firehose Box, Lifejacket Box, Battery Box etc

FRP Product Advantages

FRP Grating is a meshed square, providing molded, pultruded and phenolic gratings. The standard size is 1220 x 3660 mm, but also other sizes are available. Our gratings have a variety of types with exquisite appearance, light weight, high strength, good conductivity, easy installation and long service life. The gratings are flame retardant meeting IMO standards or low flame spread, smoke and toxicity.

The phenolic gratings are approved by USCG for level 2 fire resistance testing and can be used in some areas with special fire resistance requirements, such as the aisle of liquefied gas carriers and offshore platforms.

Advantages of Products in contradiction of steel:

- Light Weight

- Excellence Corrosion Resistance Ability

- Long Service Life

- Excellence Media Transmission Ability

- Low Coefficient of Thermal Conductivity & Thermal Stress

- Excellent Electromagnetic Insulation

- Easy Installation

- Low Operation / Maintenance Cost

GRE / GRP Product Advantages

GRE (Glass Fiber Reinforced Epoxy) pipe is a new type of composite material with the epoxy resin matrix. Our partners GRE pipes are made by the winding process. The product design complies with IMO Resolution A753 (18) Guidelines and Type Approval requirements of all the major classification societies.

The internal pressure of these kind of pipes is 16 bar and the external pressure rate is 3.8 bar. All piping systems meet the IMO – L3 level fire resistance requirement.

Typical Use of GRE / GRP Products:

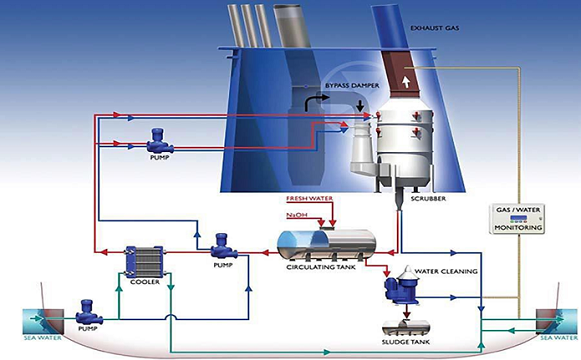

- Scrubber Installations

- Ballast Lines

- Cargo Lines

- Potable Water

- Sewage Treatment

- Steam Condensate Draining Pipes

GRP (Glass Fiber Reinforced Plastic) is a new composite material that is in increasing use in more and more marine & offshore applications, since it’s first appearance 50 years ago. This is due to its overwhelming advantages over traditional steels.

GRE Piping Materials for Scrubber Installation

The product Scrubber series include:

- Pipe

- Fitting: Tee, Elbow, Flange, Reducer, Coupling, Saddle etc

- Double O – Ring Expamsion

- Coupling and Spools

Why Choose Us for GRE – GRP Pipes</>

We provide our customers the complete solution from the early design, product manufacturing and installation to the final acceptance of the ship – owner and surveyor, including:

- Basic Technical Support, such as support span, axial load, joint strength, burst pressure etc.

- Estimate of Bills of Material

- Optimization of Design Drawings

- Pipe Stress Analysis

- On – site Training, Installation Guidance

- Design of Customized Products

- Communication with the Classification Society

- Global After – Sales Repair

Send us your inquiry via email and we will prepare our quotation as soon as possible.

Tel: +30 2130337678

Email: oceantech@ost.gr